Sepawa

Congress 2024

The growth continues –

more than ever

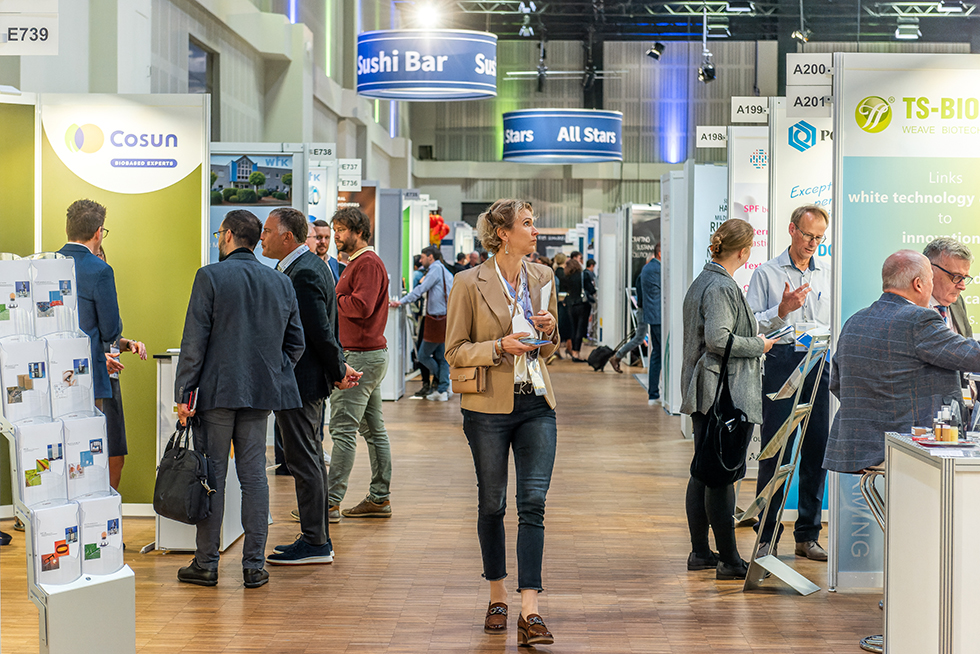

The most significant meeting point of the detergents, cleansers, cosmetics and fragrance industry in Europe.

After last year’s extremely successful congress 2023, we are looking forward to 2024 with excitement and expect numerous highlights once again. Be part of this event, exchange ideas with colleagues and forge new partnerships. Secure your participation in time.

The SEPAWA CONGRESS is

THE event with a special character.

The perfect mix of international specialist presentations, exhibition and networking.

Find out more about the topics and facts of the congress here. But you have to experience it for yourself…

Facts & Figures

Participants

Countries

Exhibitors

Lectures

Updates

Keep up to date with the SEPAWA CONGRESS and find out about the latest developments in our current updates.

FORUM FOR INNOVATION 2024 – CALL FOR PAPERS

Many thanks to

Our sponsors